Call: 08045479459

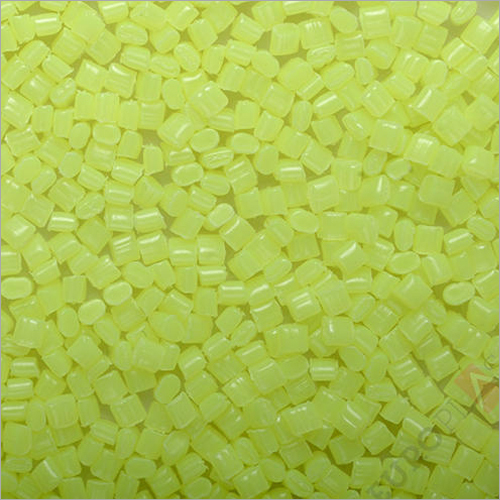

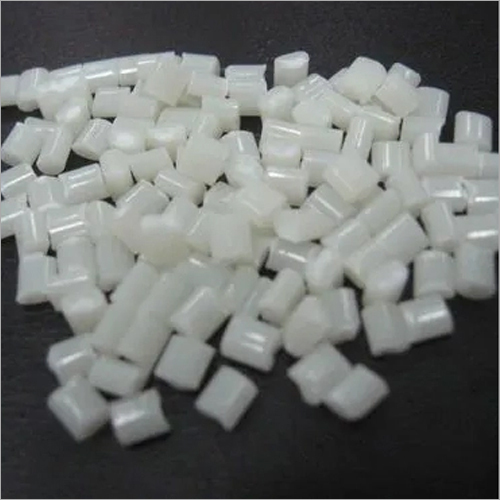

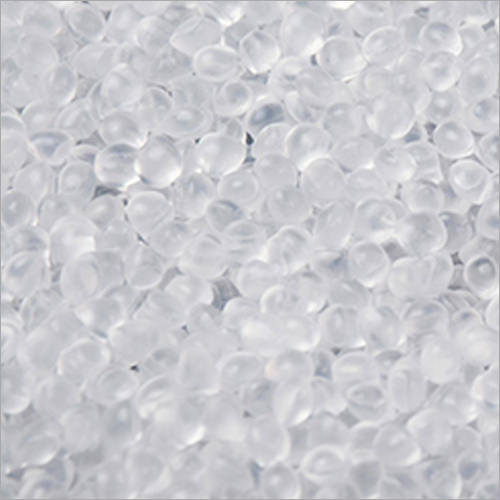

Avail our fairly priced Pearlescent Masterbatch, White Masterbatch, Anti Fibrillation Masterbatch, Transparent Filler TPT etc.

- New Arrivals

- Featured

Kashish Polymer is a leading masterbatch manufacturer and supplier, creating innovative and reliable products for the plastic industry since 2007. We offer Marble Masterbatch, Pearlescent Masterbatch, Anti Fibrillation Masterbatch, White Masterbatch, Transparent Filler TPT and more at market-leading prices. Over the past 15 years, we have become the renowned producers of these products, with many customers preferring us as their business partner.

The products are perfectly designed to fit with a variety of high-end processing techniques like injection moulding, blow moulding, extrusion, thermoforming and roto moulding. Our quality-tested products can be used for plastic bottles to car covers, yoghurt cups to tarpaulins, and multilayer and greenhouse films to pipes. Through our unique and vibrant colours and batches with excellent physical properties, we contribute to enhancing the performance of the final products of customers.

We continuously strive for better formulation of products and our world-class production facility allows us to deliver superior quality products consistently.

Team of Experts

We have a team of qualified and experienced employees, working with passion and dedication to exceed customer expectations. With their hard work, we have achieved loyalty and respect from our customers along with an excellent growth rate in the industry.

Every manufacturing stage right from weighing to mixing, twin screw extruding, cutting, cooling, sieving until bagging is performed by a team of experienced professionals. They oversee the aforesaid production activities in order to ensure serving only flawless products to customers.

Infrastructure

Kashish Polymer has a hi-tech infrastructural facility including all the latest machines and technology to manufacture products of market standard such as White Masterbatch, Anti Fibrillation Masterbatch, Pearlescent Masterbatch, Transparent Filler TPT, and more. We believe in keeping pace with the changing time and adopting new techniques as well as ultra-modern machines for manufacturing. Our aim i sto expand and support the growing demands for our Masterbatches and fulfill the specific needs of our clients.

Quality Assurance

We use tested and proven technological processes to manufacture a wide range of quality-assured colour masterbatches, additives and compounds. We have sophisticated testing equipment such as MFI Tester, and injection moulding machines for rigorous quality checking procedures. These ensure accurate test results and are crucial for our quality assurance system.

Objectives

- Quality Checks At Every Stage

- Cover Every Issue Related To Health and Environment

- Attend Customer Complaints

- Follow Procedures and Protocols Relating To Quality and Performance

Timely Order Completion

It is important to be available in the market with a ready product to meet growing demands on time. That is why we focus on speedy production process and use of modern manufacturing techniques. We produce Antimicrobial Masterbatch, Fire Retardant Masterbatch, Optical Brightener, etc., in huge quantities with zero compromises in quality. This speedy production keeps us in a position to meet the demands of local Indian markets.

Health and Safety

We work in accordance with the relevant statutory provisions and all reasonably practicable measures taken to avoid risk to our employees. The policy is implemented throughout the company and we ensure that health and safety considerations are always given priority. We devote all the necessary resources to ensure that Health and Safety is rated equal to all other functions of our business. We always strive to improve our standards and performance.

Back to top

Send Inquiry

Send Inquiry